Introduction

In the ever-evolving landscape of manufacturing, innovation is essential to staying competitive. Traditional manufacturing processes, particularly in mold making, have always been time-consuming, expensive, and prone to inefficiencies. However, as industries push toward digital transformation, technologies like Repmold have emerged as game-changers. Repmold is an advanced mold-manufacturing technology designed to optimize precision, speed, and sustainability in a wide array of sectors, including automotive, aerospace, medical, and consumer electronics.

This article will take a closer look at Repmold, exploring how this breakthrough technology is reshaping mold-making processes and transforming industries worldwide.

What is Repmold?

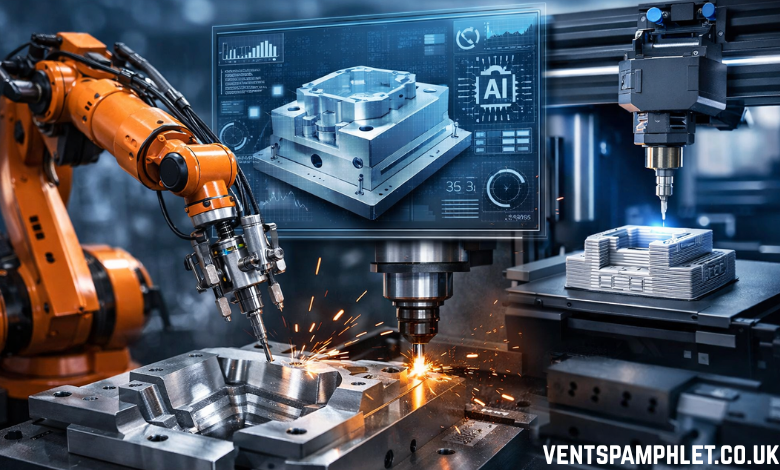

Repmold is a next-generation mold-manufacturing solution that integrates several cutting-edge technologies to streamline production. By combining additive manufacturing, CNC machining, AI-based design optimization, and sustainable practices, Repmold represents the evolution of traditional mold-making. While conventional methods could take weeks to produce a mold, Repmold’s digital fabrication approach dramatically reduces production time, completing molds in a matter of hours. This hybrid approach to mold-making ensures higher precision, greater speed, and a more environmentally conscious method of production.

The key feature of Repmold lies in its digital intelligence, which ensures that every mold produced is an exact replica of the original design, with minimal human error or deviation. It also allows manufacturers to produce molds on-demand, offering a level of agility and customization not previously possible in traditional manufacturing processes.

The Core Technology Behind Repmold

1. Additive Manufacturing

At the heart of Repmold is additive manufacturing (also known as 3D printing), a technology that allows molds to be built layer by layer using digital models. Unlike traditional subtractive methods, which require material to be removed from a larger block, additive manufacturing enables the construction of highly complex geometries with less material waste. This method offers a significant reduction in the time required to produce a mold. Additionally, additive manufacturing can create intricate, customized shapes and structures that traditional molds simply cannot achieve.

This technology has enabled Repmold to expand its capabilities, allowing for rapid prototyping and iteration. Designers can test different mold variations quickly, getting real-time feedback and adjusting designs on the fly, which is a stark contrast to the slow prototyping processes of traditional mold-making.

2. CNC Machining

CNC (Computer Numerical Control) machining complements additive manufacturing by offering precise, repeatable cutting processes. This method is crucial for shaping metal and other rigid materials to create high-quality molds. Repmold’s use of CNC machining enhances the durability and performance of molds by ensuring that intricate details and dimensions are achieved with high precision. CNC machining also contributes to the speed of production, reducing turnaround times and minimizing the need for costly reworks or adjustments.

3. AI-Based Design Optimization

Repmold integrates artificial intelligence (AI) to optimize the design and manufacturing processes. AI algorithms are used to analyze designs, predict performance, and detect potential issues before the mold enters production. This predictive modeling allows engineers to identify and correct design flaws in the virtual phase of development, reducing the likelihood of failure during physical manufacturing. Additionally, AI enables automation in mold adjustments, ensuring that each mold self-adjusts based on performance variables, making the production process even more efficient.

4. Sustainability

One of the defining features of Repmold is its commitment to sustainability. Traditional mold-making methods are resource-intensive, requiring substantial energy and raw materials. In contrast, Repmold’s use of digital fabrication techniques reduces material waste, energy consumption, and carbon footprints. Moreover, by utilizing recyclable materials and creating molds with less energy-intensive methods, Repmold sets a new standard for eco-conscious manufacturing. Companies that adopt Repmold can significantly reduce their environmental impact, while also benefiting from cost savings and faster time-to-market.

The Benefits of Repmold for Industries

1. Faster Production Times

One of the primary advantages of Repmold is its ability to accelerate production timelines. Traditional mold-making methods can take weeks to complete, but with Repmold, molds can be fabricated in just hours. This significant reduction in production time allows manufacturers to shorten lead times, reduce costs, and meet customer demands more quickly. In industries like aerospace, automotive, and medical devices, where timelines are often critical, Repmold provides a distinct competitive advantage.

2. Precision and Accuracy

Mold-making precision is paramount to product performance. Repmold ensures that each mold mirrors the original design with near-zero deviation. The integration of CNC machining and additive manufacturing technologies allows for high-accuracy mold creation, which is especially important in industries like aerospace and medical devices, where small errors can lead to costly failures. Repmold minimizes human error and produces molds with consistent quality and durability.

3. Cost Savings

The efficiency of Repmold translates directly into cost savings. Traditional mold-making processes are labor-intensive and costly, requiring significant amounts of raw material and man-hours. Repmold’s digital and automated approach minimizes material waste, reduces labor costs, and speeds up production, all of which contribute to a more cost-effective manufacturing process. Additionally, the ability to produce molds on-demand eliminates the need for large inventories, reducing the costs associated with warehousing and stockpiling materials.

4. Greater Design Flexibility

Repmold allows manufacturers to explore greater design freedom and complexity than traditional methods. With rapid prototyping, designers can test different versions of a mold quickly, adjusting parameters as needed. The hybrid approach of Repmold also allows manufacturers to produce both small, detailed components (such as medical devices) and large industrial molds (such as automotive parts) with equal ease, offering unparalleled design flexibility.

5. Improved Reliability and Reduced Rework

In traditional mold-making, rework is often required when discrepancies between the prototype and the final mold occur. However, Repmold’s integration of real-time feedback loops and AI-driven automation ensures that molds are manufactured with extreme accuracy, eliminating the need for costly rework. With every design iteration being digitally tested before production begins, manufacturers can trust that their molds will meet specifications, reducing the risk of failure and enhancing reliability.

The Future of Manufacturing with Repmold

Repmold is not just a technological advancement in mold-making; it represents the future of smart manufacturing. Its ability to merge digital intelligence, precision engineering, and sustainability sets the foundation for a new era of efficient and eco-conscious production. As industries continue to face pressure to innovate faster and operate more responsibly, Repmold offers a transformative solution.

The future of mold-making lies in further automation and AI-driven processes. As Repmold technology evolves, it will likely integrate more machine learning capabilities, further enhancing its ability to predict, adapt, and optimize mold production in real-time. The shift toward fully autonomous production lines is also on the horizon, making Repmold a key enabler in the Industry 4.0 movement.

Repmold and Sustainable Manufacturing

As the world shifts toward more sustainable production practices, Repmold stands out as a leader in eco-friendly manufacturing. Its use of recyclable materials and the energy-efficient methods it employs reduce the overall environmental impact of mold production. In an era where environmental responsibility is becoming a critical factor for businesses and consumers alike, Repmold offers a solution that meets sustainability goals while improving efficiency and performance.

Conclusion

Repmold represents a breakthrough in mold-manufacturing technology, merging speed, precision, and sustainability to meet the demands of modern industries. With its ability to drastically reduce production times, improve accuracy, cut costs, and enable greater design flexibility, Repmold has become a pivotal tool for companies across sectors like automotive, aerospace, medical devices, and consumer electronics. By integrating additive manufacturing, CNC machining, AI-based design optimization, and sustainable practices, Repmold is shaping the future of mold-making and paving the way for more efficient and responsible production processes. As industries continue to innovate, Repmold will undoubtedly play a significant role in driving the future of manufacturing.

FAQS

What is Repmold technology?

Repmold is an advanced mold-manufacturing technology that combines additive manufacturing, CNC machining, and AI optimization to improve production efficiency.

How does Repmold improve manufacturing efficiency?

Repmold reduces production time, minimizes human error, and enhances mold precision, leading to faster manufacturing and lower costs.

Which industries benefit most from Repmold?

Industries such as automotive, aerospace, medical devices, and consumer electronics benefit from Repmold’s rapid prototyping and precise mold-making capabilities.

How does Repmold contribute to sustainability?

Repmold uses digital fabrication methods that reduce material waste, energy consumption, and carbon footprints, making it an eco-friendly choice.

Can Repmold handle complex mold designs?

Yes, Repmold’s hybrid approach allows it to handle both small and large, complex mold designs with high precision and speed.